Purex Fume Extraction Guide

Purex fume extractors are among the most cost effective and efficient machines in the industry today. With their constant innovation and strive to be the leading fume extraction manufacturers in the world, we have championed this brand to be sitting in many workstations up and down the UK.

But there are still some out there who are yet to make the switch over to Purex. Well in this article, we are going to break down everything there is to know, including why your next fume extraction purchase must be Purex!

But First Lets Explain A Little About Purex Fume Extractors

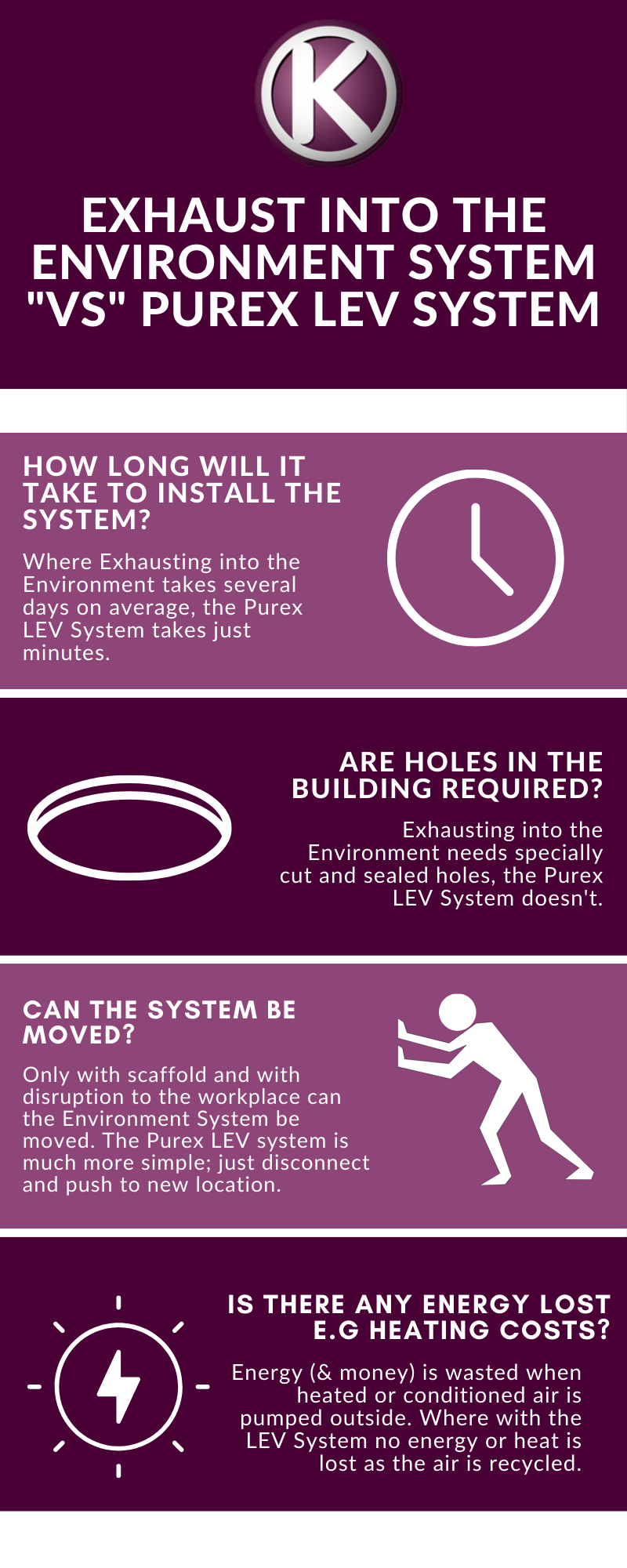

Why You Should Use LEV Systems Over External Systems

Firstly, lets highlight why we feel everybody should be using an LEV (local exhaust ventilation) system within their workplace. You can use 2 types of fume extraction unit in the workplace - external and LEV.

External – Contaminated air is collected and pumped out the contaminated air into the environment outside of the building.

LEV – Filters the air and pumps clean air back into the workplace. The unit collects pollutant particles and gases inside (adsorbed onto filters).

In addition, we have broken down the benefits of using LEV over external in the infographic below:

Type of Fume Extraction System You Need:

Firstly, you must decide upon the best Purex unit that suits your requirements. Now there are 3 main types of Fume extraction unit that you can purchase. These are:

- Digital

- Analogue

- iFume

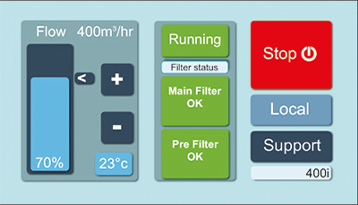

With a full colour display and intelligent detection system for when filters need to be changed, the iFume is a fantastic option for those that need a more comprehensive system.

The iFume has been redesigned from the ground up to provide features that speak to the needs of its customers. Key features include:

Filter Detection – Warnings for the operator about when a filter needs to be changed, including individual monitoring for each independent filter.

Constant Monitoring - Signals sent directly to the interface, which directly monitors the gas and particles on the exhaust of the extractor, keeping track of its effectiveness. Provides an easy way to monitor when the carbon filters life has come to an end!

Automatic Flow Control – Maintain a constant extraction rate even when the filters are blocked. The touch screen display allows you to quickly adjust the airflow as a percentage along with other critical information.

Simple & Economical – The unit is straightforward to use and adjust, with quick change filters that makes life easier for the operator. Similarly the capital costs are low, the unit is simple to relocate, and the machine is quiet whilst in operation.

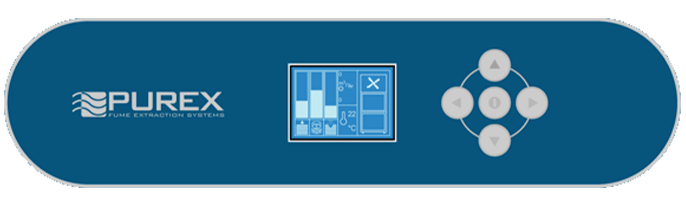

A digital fume extractor from Purex provides a visual monitoring of your fume extractor.

The features of the Purex digital fume extractors help to:

- Protect your employees by providing constant monitoring of the exhaust emissions.

- In addition they provide a simple and easy to use display that allows the operator to get all the information they need regarding the status of the machine at a glance.

- Keep a constant airflow at a low energy output, thanks to the variable speed motors that provide a fully automatic flow control system.

The analogue series of Purex fume extractors provide an economical and top quality choice for your working area, just minus a digital display.

There is no digital display on the unit. Instead, you are alerted both visually and audibly when a filter is blocked. This reduces the downtime of your unit. Each unit is capable of the following:

- Automatic electronic flow control – adjustable

- Coloured filter blockage warning system

- Simple to install & easy to move – virtually silent in operation.

- Equipped with both main & pre filters.

Standard Inclusions & Considerations Your Purex Fume Extractor

The Machine – There are many different units that you can purchase from Kaisertech. Selecting the right unit for your application and workspace is vital in conforming to LEV standards. Above all ensure that the extraction rate of the unit you choose is sufficient, and that the filtration is optimal.

Vacuum or Volume – If you have chosen a digital unit for your fume extraction, then you have the choice of either vacuum or volume sensing.

Voltage – Purex machines come in a variety of different voltages, allowing them to cater to different regions in the world. For UK compatibility ensure you select the 230V unit.

Filters – Each unit comes with the standard filters needed to operate the unit. However, each unit is compatible with a variety of other filters that are suitable for the extraction of different types of particles from the air. Look at the bottom of the product descriptions on our website for more information.

Connection Kit – Allows for the Purex fume extractor to be hooked up to a pipe or other machine – including a laser or reflow oven. Connection kits are not supplied on all units as standard. Therefore, check the listing of the product, or contact us for further clarification.

What Types Of Filters Are There?

Purex systems use a combination of two types of filters in all of their units. These are Pre-Filters and Main Filters (Commonly called HEPA filters). Below is a breakdown of the differences between the two.

Pre-Filters

Pre filters are a Purex units first line of defence. As the unit draws polluted air into the system, it must pass through the pre filter before even getting to the HEPA filter.

The pre filters act by removing and capturing the larger particles from the air, before they even have the chance to reach your HEPA filter.

They are vital in extending the shelf life of your main filter, increasing the usage you get out of your HEPA filter significantly.

Purex pre filters come in 3 main varieties, which are: Pads, Pleated Bags & Labyrinth filters.

You can get cascading bags, but these are for specialist units, for extensive fume extraction operation.

HEPA Filters

HEPA stands for High Efficiency Particulate Air. They are the main filter systems of the unit, which will remove the finer particles from the air – the ones not picked up through the pre-filter. A special combination of filter media captures gases, vapours and other particles that are released into the air from your application. Pleated material that incorporates reinforced strips for separation, helps to prevent airflow vibration or collapse in the unit.

In addition, air equalisation plates reinforce the housing of the filter. It aids in helping to distribute the airflow across the filter, ensuring you are using the entire filter media.

Each of the HEPA filters carry a unique serial number. This indicates the unit has been individually tested and certified for both safety and performance in your Purex unit.

Standard Inclusions & Considerations Your Purex Fume Extractor

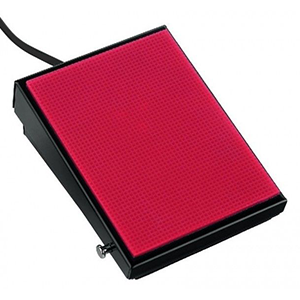

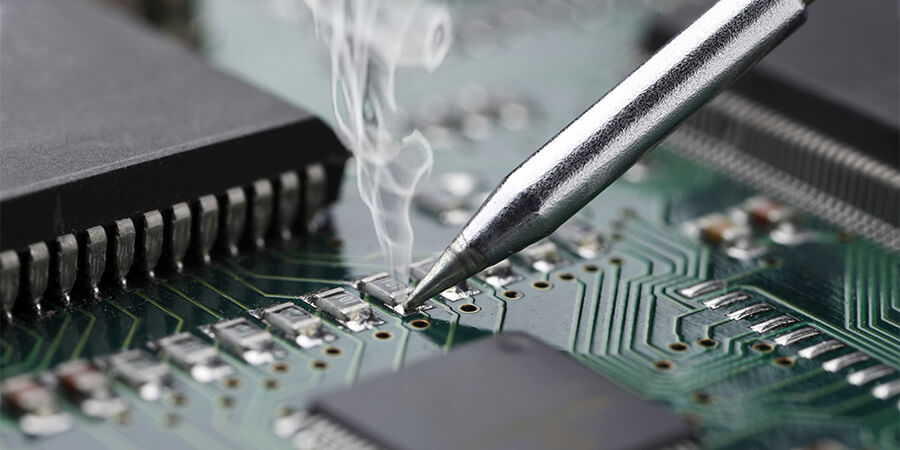

A lot of the time with fume extraction equipment, the units themselves are stowed away and out of reach. That can make getting to them a hassle, especially if the unit needs to be switched on and off multiple times a day. This can particularly be a problem for applications such as intermittent soldering, where the operation does not need to be continuous.

So, the foot pedal gives operators easy access to control the power of their units, from up to 5m away. As a bonus, conserve energy by turning off the extractor when it is not required.

The process of fume extraction is an ongoing concern in the workplace. Sadly, you cannot just buy 1 unit and then forget about it.

LEV testing serves as a means of periodically checking your workplace to ensure that the air quality is safe for everyone in and around the work setting. A qualified professional will ensure all systems are functioning correctly and that filters are not blocked.

UK COSHH regulations state Local Exhaust Ventilation systems must be tested at least once every 14 months!

There are extensive options at your disposal to accessorise your fume extractor to your workplace needs. From the pedals listed above and more, here are a few of the more popular additions to the Purex fume extractors.

Additional Filtration – Some applications may require a more extensive approach to your fume extraction process. Where this is the case, additional filters can be purchased and attached to your unit for additional filter capacity. Cascade filters can improve the life of other filters for particularly extensive applications.

Arms & Pipework – Arms, tips and other pipework kits can be bought to extend the range of your unit.

Interface Kits - Interface kits allow you to control your Purex unit from another machine, such as a reflow oven or laser machine. This lets you toggle the machine on and off and receive blocked filter warnings.

Common Questions About Purex Fume Extraction:

How Do Purex Fume Extractors Work?

Purex filters are LEV systems. They work by capturing potentially harmful fumes and particles that are circulating in your workplace.

Air is drawn into the unit and passed through a series of filters, that will remove the hazardous particles and gases. The recirculated air is then safe for the workforce.

How Often Should I Replace My Filters?

The answer to this question depends on a few factors, including frequency of use, type of application and type of Purex unit that you have in use. Use the following as a rough guideline:

- Every 12 months after heavy use

- When the unit signals the filters need changing

- When told so by LEV testing

- After detecting unwanted fumes (more below)

Should I Still Be Able To Smell The Process When Using Fume Extraction Equipment?

Any smell that comes from the exhaust of the unit, is a strong indicator that the polluting particles in the air are not being sufficiently extracted. This often means that you need to replace one of the filters in the unit. If this happens on a frequent basis, consider if you have the most optimal filter for your current application.

How Should I Dispose Of My Blocked Or Saturated Purex Filters?

The way that you dispose of each of the filters for your Purex system is different. All pre-filters can be disposed of as general waste, so long as they have been sufficiently contained in a sealed bag for example.

For the main filters, or HEPA filters, you must dispose of them as hazardous waste, and in accordance with your local disposal rules.

How Do I Know What Filters Are Compatible With My Purex Fume Extractor?

Each of the listings for our units display this information in the product description. They display the filters that come with the unit as standard when purchased. Listed below are the other compatible filters for the unit.

As a result, if you search up your unit on our website, you will be able to see the compatible units listed there, along with a link that takes you directly to those filters.

To Conclude…

To sum up, Purex have a lot of flexibility in their product range, meaning they have a unit that will suit your application.

For more on the benefits of a fume extraction system in your workplace, check out our article below

For any assistance in selecting any of the Purex range, feel free to contact our team on 023 8065 0065.