When creating the ideal workplace set up for you or your employees, fume extracting equipment must be considered a priority.

Manufacturing work such as soldering cause thermal breakdowns and oxidisation, causing harmful particles to be released. This is in fact one of the biggest risks to health that site workers face in the modern day. Fume Extractors are a way of combating this.

This article details the benefits along with the types of filtration systems that you can purchase with Kaisertech. Moreover, if you already know the benefits of these and want a breakdown of the types of units available. Read on for our analysis.

What Is Fume Extracting Equipment & How Does It Work?

During the operation of equipment in a production environment, toxic fumes and dust particles are often airborne. Fume extracting equipment will act as a defence to these by extracting and filtering the particles from the contaminated air. The filtered air will then be released back into the environment, free from the contaminants.

Fume extractors work because of the suction created through an internal fan. This draws the air into its internal filtration system. Hence, a pretty simple way to keep the air you breathe around your workstation nice and clean.

Furthermore, you can purchase a variety of different fume extractors. Each of these cater to different environments workspace constraints. But we will expand on this further down.

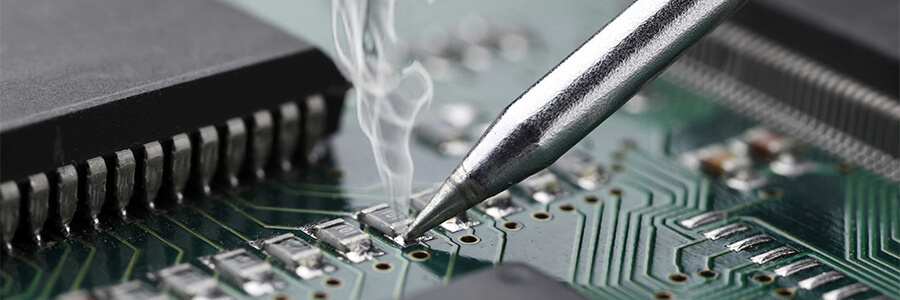

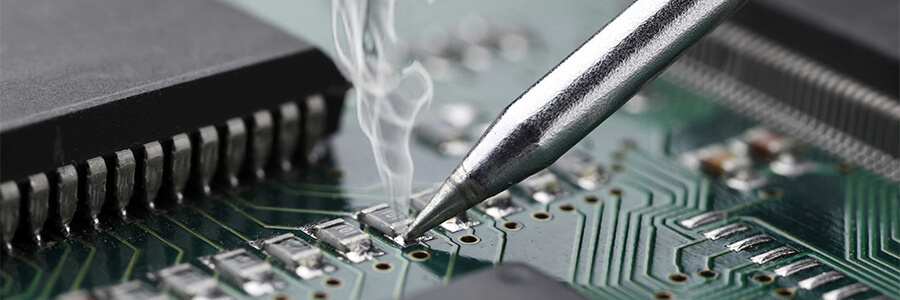

How Are Soldering Fumes A Risk To Workers?

Soldering, like many other kinds of manufacturing work such as welding, emit fumes during the process. The particles and gases that are created during the process can be harmful to the operator. It doesn't matter what type of soldering work you carry out. All soldering works generate fumes that, if not appropriately dealt with, can cause harm to the operator after long-term exposure.

But I Thought Lead-Free Soldering Is More Environmentally Friendly?

Well yes, but like with most things in life, there are certain trade offs. Lead-free soldering has a higher melting point than leaded solder,

requires both a higher temperature, and often more flux to complete the process. The solder smoke that is emitted during this is often full of finer dust particles that are more easily breathed in by the operator.

So What Happens During The Soldering Process?

Now, specifically during hand soldering, if the correct fume extraction equipment is not used, the fumes will rise, becoming breathable for the user. What's more, without the appropriate fume extraction systems in place, other in the room are at risk of breathing in the harmful particles.

Long term exposure to soldering fumes and other chemicals can cause permanent lung damage, with the sufferers often never being able to return to soldering work. Hence why it is essential that solder fume exposure is kept as low as is reasonably practical to do so!

Benefits Of Using Fume Extraction Equipment

Chances are that fume extraction may yet to have crossed your mind. Well here is why you should take it seriously:

1 - Less Contamination In The Workplace

One of the obvious benefits are less particles in the air that can be harmful if inhaled. Workplaces that require heavy soldering or welding need a clear airflow to reduce risk of harm to your employees.

Fumes from welding can contribute to lung cancer, with soldering fumes not fairing much better. Rosin-based solder fumes are regarded as one of the most significant causes of asthma in the UK. Even small amounts of fumes can cause an asthma attack to flare up.

It is for this reason that fume extractors are so important in ensuring the air in your working environment is breathable. That way, by filtering the contaminants, the employee is at a reduced risk of the above mentioned health risks.

2 - Healthier Work Environment

According to HSE England, Roughly in the UK, there are 32.5m working days that are lost through work related ill health. That works out to averagely 20 days per employee.

Fume extracting equipment promotes a cleaner and better circulated airflow in the workplace. With the correct unit and sufficient filtration system you leave your employees less prone to work related illness. This translates into a happier and more productive workforce.

3 - Compliance With HSE

Working with solder or welding fumes, there are certain HSE regulations that you must comply to. Fume extractors help you meet the requirements for the COSHH 2002, ensuring you keep the health risked posed to your employees to a minimum.

As you have read from the risks outlined above, there are many dangers posed by the inhalation of fumes.

Therefore, ensuring that the correct fume extraction equipment is in place helps keep your workplace from failing any health assessments that will need to be carried out.

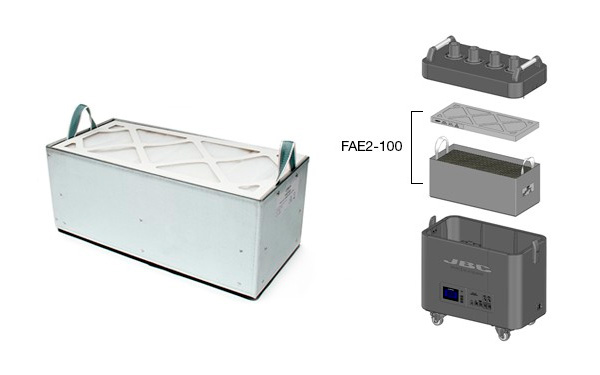

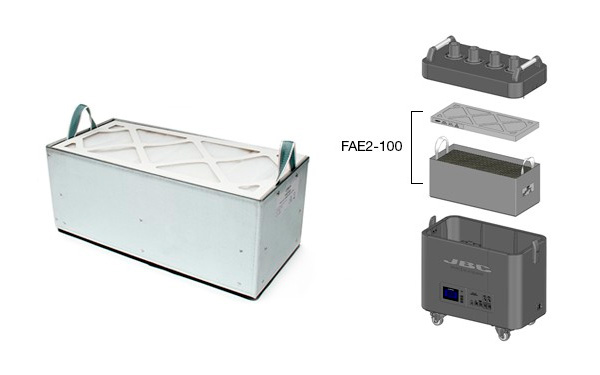

Types Of Fume Extractors Available At Kaisertech

There is no one size fits all solution that caters to every working environment. Each setting will require different level of filtration, from simple compact units to production grade systems.

The location that you decide to place your extraction equipment will largely depend on two factors. The work conducted, and the space that is available in your workplace. Therefore, there are also different types of units that you could purchase including; equipment mounted, worktop, vents, portable, or standalone units.

Choosing the optimal unit will give you both the best value for money and the best clean air solution for your business. Here at Kaisertech, we provide a comprehensive range catering to as many needs of our customer base as possible.

Below are five main types of fume extraction solutions that we can offer you.

Soldering Tip Extraction

These types of extractors connect directly to the handpiece of the soldering iron. They extract the fumes generated directly at the solder joint. These are easily clipped to the handpiece and can be removed for easy maintenance. You will require a suction pump and filter. But once you have those, this type of fume extraction is the perfect addition to JBC handpieces such as the T245, T210 AP130 and more.

Cowl Fume Extraction

These units are ideal for single user stations that involve low volumes of hand soldering or other low-level operations. Spatially efficient, they lie horizontally across your workbench, capturing the fumes before they are able to reach the operators breathing level. Plugged onto the FumeBuster, this is an ideal attachment should you only partake in infrequent soldering requirements.

Arm Extraction Units

Investing in a fume extracting system with arm extensions is the perfect addition to any production workspace. The units are lightweight and moveable, making them perfect for companies where workspace is sparse. You can easily store these units under your desk or on top of a workbench. Furthermore, with an arm extraction unit, you can easily relocate should your work operations need to be shuffled around.

Digital Fume Extraction Systems

Require fume extraction for wave soldering, laser engraving and much more? These units allow you real control, catering for wave soldering, laser engraving and much more. They are simple to install and almost silent when in operation, making as little distraction to your workplace environment as possible. These systems are programmed to maintain constant extraction rates - even with blocked filters. Thus, making these units the ideal investment to keep your the air in your workshops free from contaminants.

Downdraught Benches

A downdraught bench is one of the more comprehensive and sophisticated bits of fume extracting equipment in our catalogues. The main benefit of these is the integrated downdraught and fume extraction feature. In summary, the bench collects the contaminants in the air as you are working. This helps makes downdraught benches environmentally friendly and ideal for employers who need to adhere to strict health and safety regulations. No matter if you are welding, grinding or soldering, these benches cover a large area and are perfect for a heavy duty workshop!

Common Work That Requires Fume Extraction

Without knowing it, the work undertaken can generate fumes that need extracting from the correct LEV systems. The following generate a high volume of fumes that, if not correctly dealt with, could leave a workforce at risk:

- Soldering

- Welding

- Grinding

- 3D Printing

- Painting

- Conformal Coating

Whether your processes are industrial or DIY, ensuring that you have the correct PPE and fume extraction in place is paramount to your long term good health!

To Conclude

Hopefully in this weeks blog we have given you a good indication as to the importance of the clear airflow that fume extractors provide to your workplace. Providing a safe environment long term is in the benefit of your employees and business owners, increasing both productivity and well-being!

Should you have any questions or queries about what type of fume extraction would best suit your place of work, do not hesitate to contact our expert team. They will be able to discuss your place of work and diagnose the unit that is most appropriate to your needs. Call us on 023 8065 0065 or email us at [email protected].