Always on the cusp of innovation, JBC continues to provide the most cutting edge in soldering technology. Last month, they released their new Auto-Feed Soldering Station, the ALE-210VA.

This builds upon the success of the AL and SF series of solder feed stations.

We had the opportunity to speak with Sergi Churio, Electronic Lab Manager at JBC, to discuss the ALE in greater depth. What improvements are there, the solutions it provides, and what is its place in the market?

Continue reading below to learn more from the brains behind the ALE!

Let’s Discuss What The ALE Is Improving Upon

As part of JBC's premium line of soldering stations, the AL has been their Auto Feed soldering option.

An auto-feed soldering station both solders and feeds wire through one handpiece. This is ideal for applications that need a free hand whilst soldering.

Expanding on this was the release of the SF solder feeder station.

The experience gained through these two models allowed JBC to harness their best features. They have combined JBC's exclusive heating system with precise wire dispensing capabilities. Born from this is the ALE - the perfect station for repetitive soldering tasks.

“For manufacturing processes, it is important to obtain both reliable and repetitive products,” says Sergi.

“Therefore, it is mandatory to have both an efficient and high-quality hand soldering process. The amount of solder fed during the soldering process has a direct impact on the product quality. Although it is not the only threat that can cause a failure.

“A feeding control that is precise and automated will help to achieve a reliable and repetitive production process.”

Why Was It Important To Upgrade?

When creating any product, it is important to gauge the exact problem it will solve for the operator.

Improving soldering efficiency lay at the heart of JBC’s thought processes when it comes to the ALE. A human-centred approach to the development of this product was crucial.

“We recognise that operators often develop innovative feeding and fixing techniques when using standard tools,” says Sergi. “The reality is that some tasks almost need a third hand.”

“The ALE presents an easy way to solve this issue.

“Providing all of JBC’s soldering technology in one hand, along with a high-precision feeding system, the operator can shift their focus onto the quality of their soldering.

“They no longer need to worry about how they hold the solder wire and component whilst also soldering.”

Solutions Provided By The ALE

Benefits And Upgraded Features

The ALE provides many benefits. Each of these makes the operator's soldering experience ever more streamlined.

“Our aim was to build upon the experience and feedback we have gained from the SF and SFR product design,” says JBC. “This allowed us to bring the concept of the ALE into reality.”

So, let’s discuss the added benefits that ALE can bring to your workplace.

JBC’s Exclusive Heating System

Soldering stations manufactured by JBC, have become synonymous for their exclusive heat management systems.

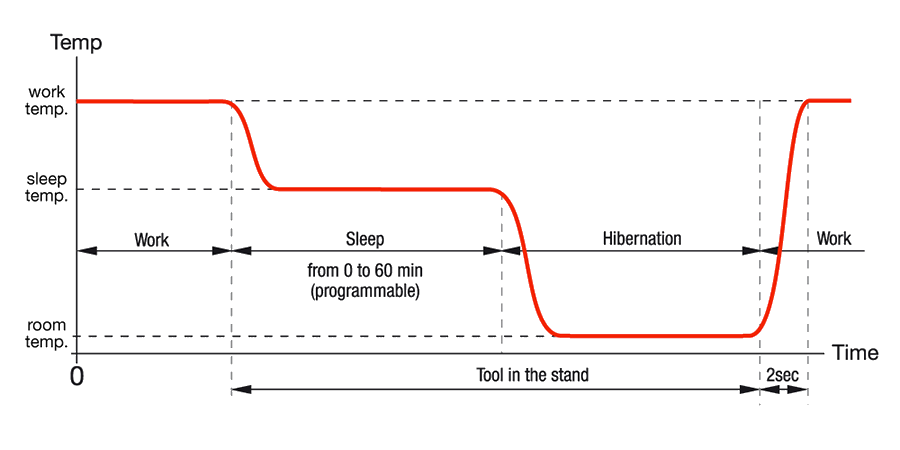

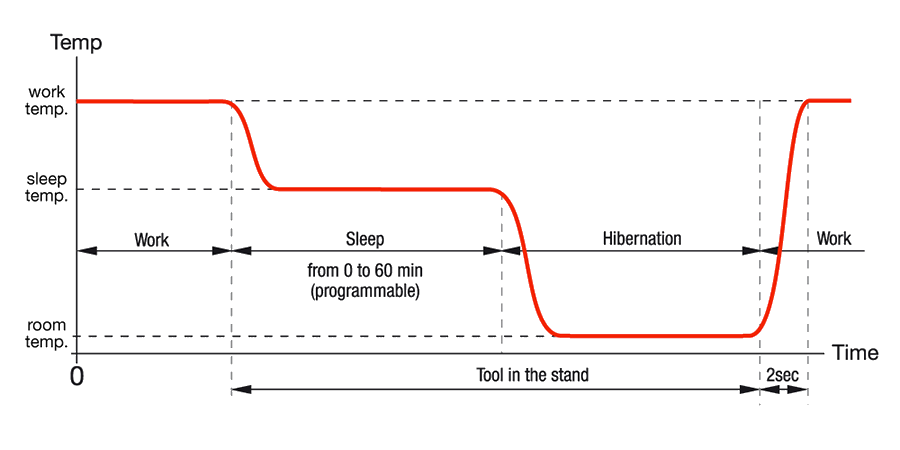

The sleep and hibernation modes help extend the life of soldering cartridges by up to 5 times. This is largely thanks to their lower operating temperatures.

The ALE incorporates this technology.

“The new ALE development allowed us to combine a precise solder wire dispensing device with JBC's exclusive heating system. This made an all-in-one auto-feed soldering station,” explains Sergi.

“The specially designed interface also allows operators to create proper soldering profiles. Each soldering task you undertake can have a new profile.”

Precise Wire Distribution

The ALE includes 3 working modes for the dispensing of your solder. These can be effortlessly switched between through the touch of a button.

This gives the user full control of the solder dispense rate. A user-friendly interface also aids the operator in having complete control of every part of the soldering process.

“Through only the press of a button, the ALE feeds precisely the programmed amount of solder wire,” says Sergi. “This makes the ALE perfect for repetitive soldering jobs, especially on the production line.

“You can toggle the station feeding mode to best suit your needs - whether that be continuous, discontinuous, or program mode.”

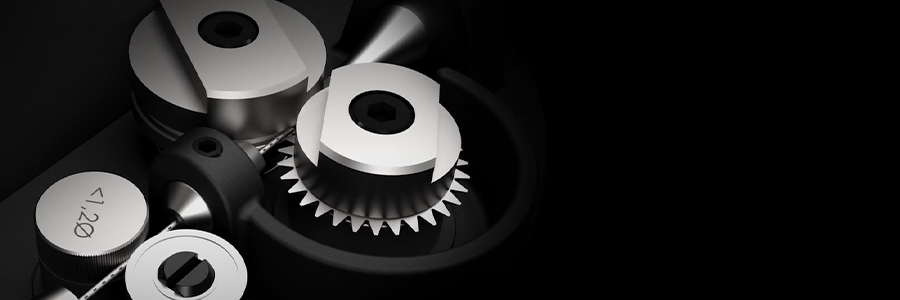

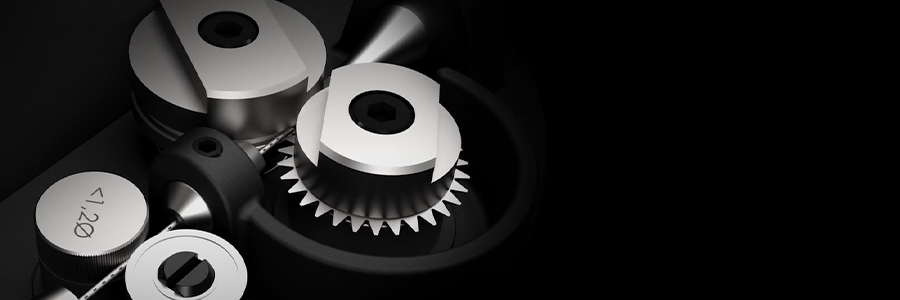

Solder Perforation

The driving theory behind perforation devices is that they allow the gasses created whilst soldering to escape more efficiently. In turn this reduces defects and allows an improved bond to take form.

Along the solder feeder of the ALE, there are small rotating blades, which pierce small holes in the wire down to the flux core - whilst the wire is being fed through.

As mentioned above, this solder perforation technology allows for improved flux flow and outgassing - helping to cut solder splatters and spitting.

“The ALE brings obvious benefits to your soldering process such as the constant and repetitive solder feeding. But the solder perforation technology is another huge improvement” says Sergi.

“Important improvements such as wire perforation down to the flux core, allow for greatly improved flux flow. This also avoids issues brought about by flux splashing due to outgassing.”

You can read more about the problems associated with solder splashing and outgassing here.

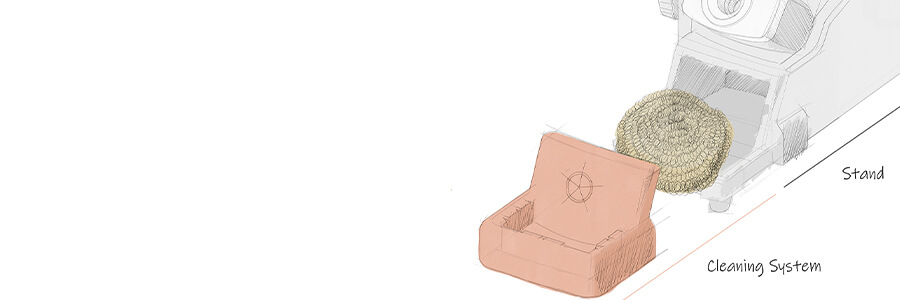

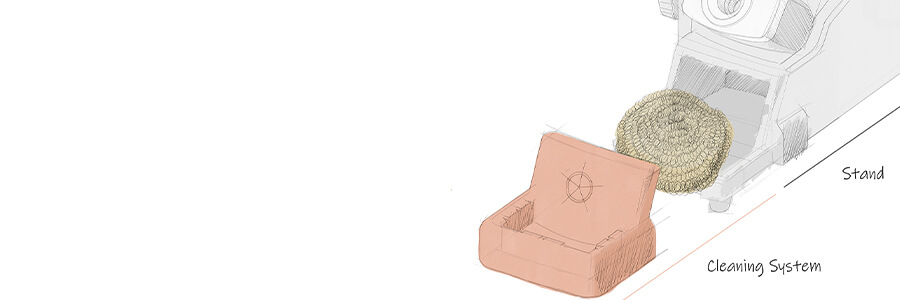

New Incorporated JBC Stand

JBC has, within the last month, upgraded its entire stand range. These have now become a 2 in 1 system that incorporates both a stand and cleaning system into one unit.

Not only can you store up to 4 cartridges and effortlessly snap between tips - But you are also able to better prevent oxidisation through tip cleaning.

“All of these systems combined into just one device shrinks the footprint of the stands significantly,” says Sergi.

“This saves space for the operator on their workbench, whilst also keeping the area clean.”

All new JBC stands also incorporate an antisplash membrane. This will keep your working area clean from any foreign solder particles. As illustrated in the image above, you can use metallic wool or a sponge for your cleaning needs.

The built-in integrated wiper also helps you to remove excess solder from your tip effortlessly with one hand.

Challenges & Where The Auto-Feed Soldering Station Fits In The Market

Like with any product improvement, there are certain challenges that must be overcome to reach perfection.

One of the tweaks that the AL-2A required was its ability to carry a larger solder reel. For applications that required a volume of solder higher than 0.5kg, the AL required reloading of the reel to resume the process.

To improve upon this, the ALE needed to cater to higher weight capacities. Therefore, this required smart design decisions.

“In an attempt to minimise maintenance stops, we set out from the start with the objective of having the ALE carry a big solder reel - Not just your typical 0.5kg reel,” Sergi explains.

“We designed the station to manage solder reels up to 2kg.

"There are several jobs where the ALE will be the perfect tool. But we would definitely recommend it for cable and connector soldering.

"Operators will reduce the assembly and fixing time. In turn, this will increase the efficiency, all by switching to using our new ALE auto-feeding soldering station."

Kaisertechs Sales and Marketing Director Adam Sibley has been hands on with the ALE for the past few weeks, and has gathered feedback on the unit from a number of customers across the UK.

"Many of our current customers and solder wire suppliers have provided incredible data and feedback on the performance of these types of solutions" says Adam.

"We are delighted to have the opportunity to present this technology to our customers here in the UK."

To Conclude...

As detailed above, the ALE has had a significant upgrade when compared to its predecessor - The AL-2A.

JBC has harnessed what we loved about the AL, SF & SFR range - crafting an auto-feeding soldering station that is truly unrivalled.

We would like to thank Sergi for his time. We hope you are all as excited as us to get your hands on the new auto-feed soldering station from JBC. Harness the improvements and let us know how the ALE has helped your workflow.

Should you require further information on the ALE, or wish to upgrade your system, contact us today. Our support team can be reached through email ([email protected]) or over the phone (023 8065 0065).