Why JBC Soldering Tips Produce Premium Results:

Ensuring that you select the best tip for each soldering application increases your productivity and reliability. JBC soldering cartridges are constructed with 4 layers – copper core, chrome layer, iron layer and a tin layer.

After extensive use, even the most cautious of soldering practitioners will need to replace their soldering tips. The plated on the tip of the soldering cartridge will wear and hollow out, exposing the copper core – a strong indicator that the cartridge has reached its end of life.

Once this happens you will need to replace your JBC cartridges.

Benefits Of JBC Cartridges

Efficient Heating System

JBC systems benefit from an exclusive heating system – aiding in an extremely quick tip temperature recovery time. Subsequently, the operator can work at lower temperatures. It takes JBC systems to reach a tip temperature of 350ºC in only 2 seconds – whereas other soldering brands can take in excess of 10 seconds. This is thanks to the fully integrated thermal sensors in each of the tips, ensuring rapid temperature recovery.

Long Tip Life

The life of your soldering tips increases significantly when using lower temperatures. When using JBC equipment you benefit from their sleep and hibernation modes. Sleep mode places the tool in a state of rest when not being used, automatically lowering the temperature below that of solder melting point. After a further period of inactivity, hibernation mode kicks in. This cuts power to the tool, leaving the soldering tip to reach room temperature – helping to save power and reduce oxidisation.

Over 500 Variations Across The Range

The sheer breadth of cartridge selection makes JBC soldering equipment cater to even the most obscure of applications. From different shapes to sizes, the JBC cartridge catalogue offers bespoke solutions for even obscure soldering or rework tasks. The methodology behind each JBC soldering cartridge is to satisfy the following 3 criteria: supreme heat transfer, instantaneous heating up and great durability.

Selecting The Best JBC Soldering Tip

There are several factors that go into the selection process for the most appropriate soldering cartridge for you application. These include:

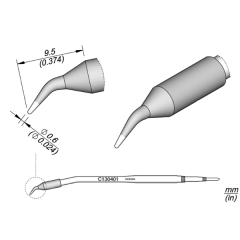

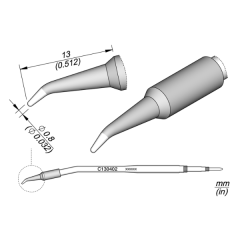

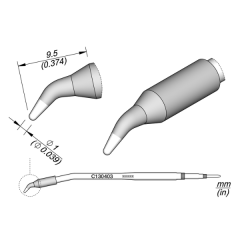

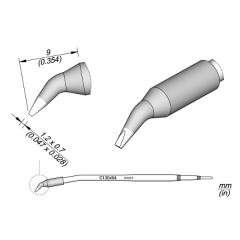

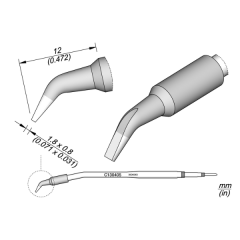

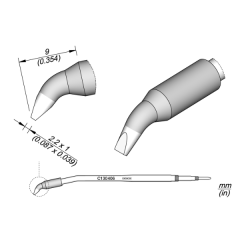

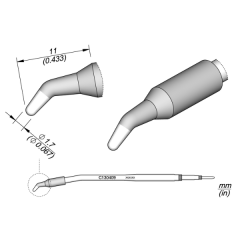

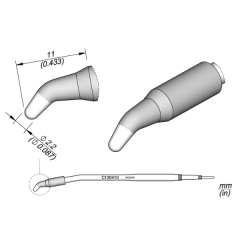

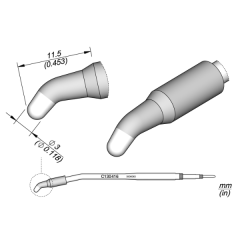

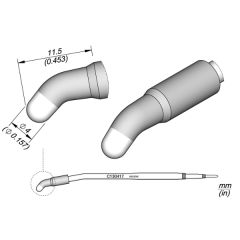

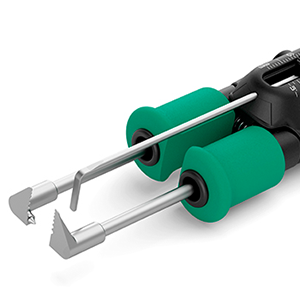

Shape & Size Of Cartridge

The geometry of the soldering cartridge you select needs to be applicable for the soldering task at hand. JBC provides special geometry tips that can cater to almost any task you conduct, whether that be through-hole, drag or soldering for other more bespoke components.

Contact Surface

As a rule of thumb, you want to select a cartridge that covers the greatest area of contact possible with the parts being soldered. This ensures the best results for thermal transfer. JBC strikes the perfect balance between duration and thermal performance. Thanks to the enhanced geometry, soldering cartridges from JBC are 40% faster and more efficient than standard tips.

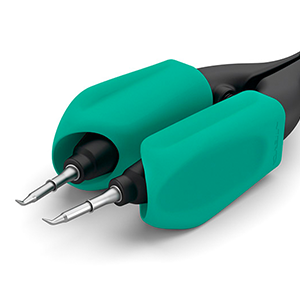

Tool Selection

The tool you select will dictate the range of JBC soldering cartridges that you have at your disposal. You can follow the JBC cartridge guide here to find out what tips and shapes are compatible with the handpiece you have or plan to use.

Make Your JBC Soldering Cartridges Last

No matter how much care you take, eventually, through prolonged use, your soldering cartridges will require replacing. But there are definitely steps that can be taken to extend the life of your soldering cartridge. These include the following:

Tin Your Tips – In order to ensure maximum thermal transfer is achieved, you must tin your cartridges before and after each use. Simply apply a small layer of solder to the cartridge. This acts as a layer of protection between the soldering tip and the outside air – which in turn limits the process of oxidisation.

Clean Your Tips – The cleaning routine you have for your soldering cartridge has a direct impact on the tip life. For the best thermal transfer, the tip must be clear of oxidisation and solder residue. There are a number of methods you can use to clean the tips, however, always ensure that you use the cleaning methods recommended by JBC.

Soldering Technique – There is no correlation between pressure applied through the handpiece and thermal performance. In fact, if you apply too much pressure through the soldering cartridge, all you are doing is causing possible damage. Surface contact is sufficient, any more pressure is overkill and not required.