ESD Flooring For Industrial And Commercial Use

ESD Flooring For Commercial & Industrial Use

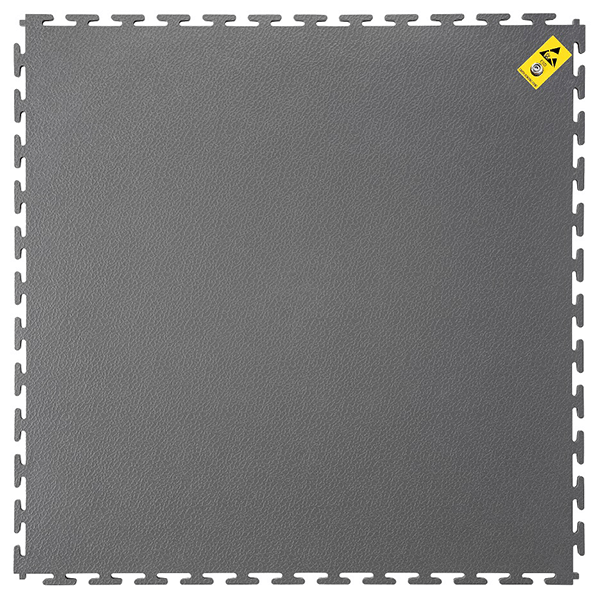

Conductive, Dissipative and Anti-static Electro-static Discharge Floor Tiles , Manufactured In The UK

- BS EN 61340-5-1 and IEC 61340 compliant

- Made in the UK

- Life time guarantee of ESD performance

- Easy to install

- Environmentally sustainable

Benefits Of Using Our ESD Flooring

Discuss Your Requirements

Our team are knowledgeable regarding all aspects of setting up a static safe environment. We can help make the best suggestions for your current work set up. We have years of experience helping to set up EPAs across the UK.

Provide Measurements

Our team are knowledgeable regarding all aspects of setting up a static safe environment. We can help make the best suggestions for your current work set up. We have years of experience helping to set up EPAs across the UK.

Delivery & Installation

Our ESD flooring is shipped directly from the manufacturer, with lead times depending on the specifications of your order. This flooring can be installed by yourself, or we can have it professionally installed on your premises.

Features Of Our ESD Flooring Tiles

- Suitable for trucks, HGVs and heavy-duty applications

- Install without downtime

- 10 year warranty

- Withstands tight turning circles

- Ideal for uneven or damp floors

- Good chemical resistance

- Expected lifespan of 20 + years

- Exceptionally durable & simple to install

- Noise reduction of up to 46db

- No damp proof membrane, screed or adhesives required

- Fire retardant – Class Bfl S1

- Easy to maintain & clean

- Excellent slip-resistance (R10)

- Reduces worker fatigue

- Warm – Insulates the floor from cold

- No additional toxic chemicals, 100% recyclable

Composition, Manufacture & Availability Of Our ESD Floor Tiles

Composition

The ESD floor tiles are comprised of stainless-steel fibres, added throughout the inner structure of the tile. These microfibres draw the current away from the surface through its entire thickness.

Considerations

ESD flooring must be installed over a grid of conductive tape. This helps to unify conductivity through contiguously installed tiles. These ESD floor tiles should be used in conjunction with other ESD measures including footwear etc.

Post Installation

You must ensure that your floor meets industry specific standards. Ongoing testing needs to be conducted, along with the appropriate cleaning regime. Read more information on the link below.