Through 2023, we were privileged to be able to work on numerous projects up and down the country. From the automotive industry, sporting world with Formula 1 and of course the electronics industry.

Each provided us with a glimpse into just how many sectors can benefit from the use of JBC equipment. We have always described this equipment as the crème de le crème of soldering equipment. Once you pick up the tools and use them for the first time, there really is no going back to other brands.

With this being said, we would like to showcase one of our prouder projects from last year.

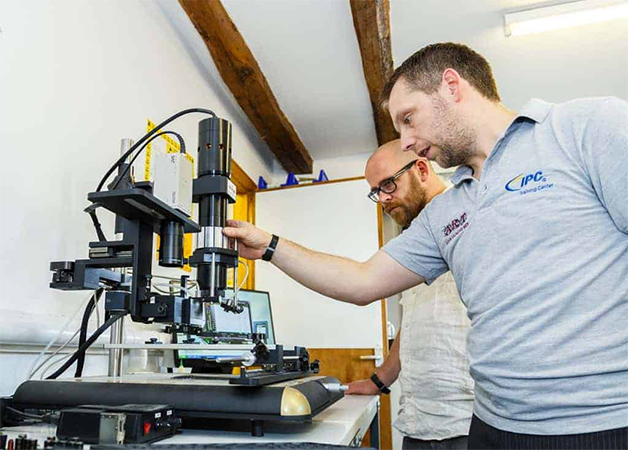

Towards the tail end of the year, we helped to modernise the soldering equipment in the training centre for Advanced Rework Technology (ART).

They are one of the longest-running IPC Certification Centres in Europe, providing training with the latest soldering and rework equipment.

We had the chance to speak with John Vickers, One of the Master IPC Trainers at ART, to get further insight into the upgrade of their soldering equipment at their HQ in Witham, along with learning a little more about ART.

| Article Contents | |

| Who Are ART | |

| Project & Requirements | |

| Solution | |

| How Kaisertech Helped | |

| First Impressions |

Who Are Advanced Rework Technology (ART)?

KT - So John, could you tell us a bit about who ART are, the services you provide and how ART is different to other training centres?

JV - "We offer bespoke IPC training for beginners to expert level operators with hands-on soldering classes. This includes process consultancy, inspection plans and auditing preparation.

"We support the courses and standards taught by being active members of the committees that write the documents, standards and their associated training curriculums.

"This puts us a step above other training providers, as we not only teach the subjects but can provide the additional support to our customers with information, not just on industry changes but also why the changes were made.

"This is vital to support the high quality of our training services."

KT - Can you go into more detail regarding the IPC training and support offered by ART?

JV - "We are one of only 2 training providers worldwide that are able to offer all IPC training classes to any accreditation level.

"These classes range from PCB design, bare board acceptance, process requirements, assembly acceptance, rework repair and more.

"We pride ourselves on delivering the best possible training. We believe that what elevates us is the support we offer after the training has taken place. All students are taught how to access support dependant on the issue they have.

"Our students will know who and how to contact for any help that is required."

Project Scope & Requirements

KT - What were your initial reasons for upgrading your existing equipment?

JV - "In order for us to offer the best training and service to the industry, we feel that we must also use the latest and best equipment to support this.

"We looked at many different brands, but with the wide range of both handpieces and tips, we believe the JBC equipment will meet all the requirements for our ongoing training objectives."

KT - What requirements did you have for your new equipment?

JV - "We have a large number of classes, from soldering and rework classes on printed circuit boards and assemblies, to additional technologies such as fibre optics.

"To facilitate this, we require equipment with a full range of tip geometries, a wide temperature range and also handpieces running from the same control unit."

KT - What ultimately led to you deciding to trial and make the investment in JBC equipment?

JV - "Who better to ask than customers and OEM/CEM's within the industry.

"The best advice is also from those using the equipment on a regular basis. The team at ART had gathered such positive feedback from those already using JBC equipment day-to-day."

The Solution

Once ART knew they wanted to trial JBC equipment, they contacted Kaisertech, being an official distributor within the UK.

We then demonstrated the capabilities of a JBC modular setup, in particular, the DMSE 4 tool station.

This involved a demo on site, showcasing the adaptability, power and performance that all JBC equipment can provide.

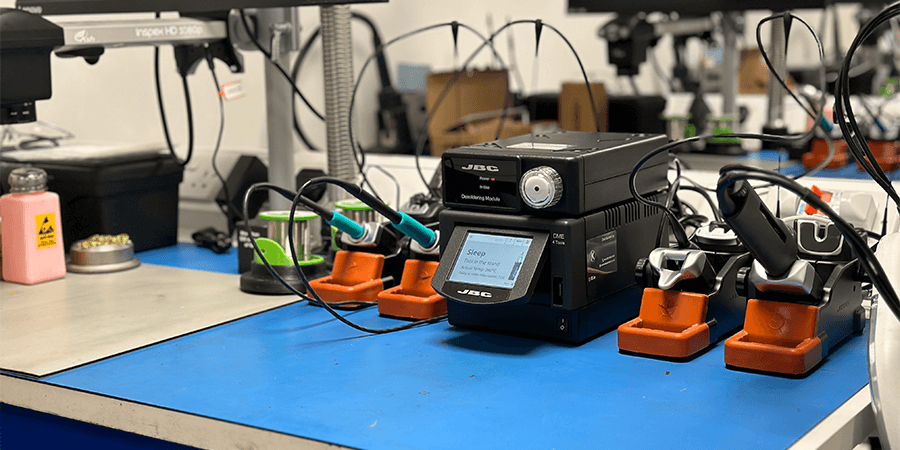

This led to the investment in 10 DMSE set ups for their site in Witham.

The modular set up consisted of:

- DME 4-tool control unit

- T245 – general purpose

- T210 – precision handle

- AM120 – Tweezer handpiece

- DR560 – Desoldering handle

- MSE Desoldering model

- Wide array of JBC cartridges

This was suggested for several reasons, which are outlined below :

Flexibility Of The Equipment

With the DME, you can have 4 tools operated from 1 control unit. This catered to ARTs need to offer training across a broad spectrum of applications. Connected tools can be used simultaneously, meaning multiple people can operate from the same control unit.

This also helps to save space, with no need for multiple stations to control each tool.

Wide Tip Range

As John alluded to previously, ART needs to ensure that they cater to a wide variety of applications across multiple sectors. To do this, there must be a wide variety of tip geometries and shapes compatible with the tools.

JBC boasts over 500 shapes and sizes of soldering tips. The T245 handle alone can cater to over 19 shapes.

This made JBC the obvious solution!

Intelligent Heat Management

JBC are market leaders for providing efficient heat management technology when soldering. Automatic detection technology in each of the stands allow the tools to enter sleep & hibernation modes when not in use.

This increases the tip life exponentially, extending the tip life by almost 5 times.

Support Provided By Kaisertech

KT - How did you find the support provided by Kaisertech through your entire process?

JV - "The support ART Ltd recieved was second to none.

"Being novices to the new JBC equipment, we relied heavily on Kaisertech to assist in supporting us. This ensured the investment in the handpieces and tips met the needs of the commonly used components often used in our training courses.

"We therefore had everything available for our first course presented using the equipment. This prevented any reduction on the high quality of our training courses."

What Are The First Impressions After The Upgrade?

KT - What are the first impressions of your new JBC setup?

JV - "First impressions for anyone that sees the JBC equipment is just how good the systems look.

"Luckily it's not style over substance. We have found the DME 4 tool unit and desoldering modules to be intuitive, easy to set up and simple to use."

KT - How have your students responded to using the new equipment in your training facility?

JV - "The first thing to understand is that most students have used various soldering set ups, they may not be using JBC where they work.

"So firstly, we show how the equipment needs to be used. Once that's completed the students are then free to see how it works for them.

"And I must say that the feedback has been positive. The students like both the look and feel of the handpieces, along with the speed at which they heat up, coupled with the dual system of sleep for non-use into hibernation."

In Summary

Hopefully this case study has helped share an insight into how Kaisertech helps to support their customers from start to finish - or from concept into reality.

Thank you to ART for trusting us with the install of their new JBC soldering set up. Should you require any IPC training, reach out to them and experience the true luxury of a JBC soldering experience.

If you require any help with upgrading your own equipment, whether that be soldering setups, benching, auromation or beyond, reach out to our team today. You can email enquiries over to [email protected] or give our team a call on 023 8065 0065.