A Recap Of Productronica 2023

This November, our team had the privilege of attending Productronica, held at the Messe München in Munich.

Productronica is the world's leading trade fair, presenting the entire range of technologies and solutions for electronics manufacturing. It provides in-depth insights into the latest trends and live demonstrations for new products across the industry.

Let's dive into the key discoveries and exciting new products that stole the spotlight for us at Productronica 2023.

Key Discoveries:

Productronica 2023 was a mosaic of industry trends and innovations that shed light on the future of electronics manufacturing.

From the rise of sustainable practices to the integration of artificial intelligence in production processes, the event highlighted the industry's commitment to innovation and efficiency.

One noteworthy trend was the increasing demand for eco-friendly practices in electronics manufacturing.

Many companies showcased their efforts in reducing their carbon footprint and implementing sustainable solutions, reflecting a broader industry shift towards environmental responsibility.

New Products On The Horizon!

JBC

To kick off the most anticipated part of the blog, let’s start with the world’s leading soldering brand JBC!

JBC has always believed that the future of hand soldering is one of the true drivers of innovation, and this year, they definitely impressed with their new product launches.

The Updated B-IRON & New BIRON Dual Is Out!

The most anticipated product from JBC is of course the latest version of the B-IRON!

With the latest battery improvements combined with JBC Most Efficient Soldering System, B·IRON becomes the new generation of soldering irons.

B·IRON 210 performs up to 500 SMD soldering joints per charge and is specially designed for soldering SMDs.

Key Features:

-

B210 precision handle is fully compatible with C210 Cartridge Range. It also has a power safe mode that can be activated by putting on the cap.

-

Charging base charges the tool automatically when placed in the tool holder and allows adjusting the angle to suit the operator´s needs.

Hot Air Just Got Bigger!

Picture a world where precision effortlessly pairs with versatility, handling delicate tasks while also taking on bigger, more high-mass solder joints.

JBC has now made this possible as the JNAU station handpieces upgrades its J325 nozzle game - moving from the finely tuned 1mm diameter to the sturdy 3mm diameter.

This expansion allows for a wider range of application, working with larger components.

Key Features:

Perfect for reworking SMDs on areas with minimal separation without affecting nearby components.

JBC Exclusive System enables the regulation of temperature and air flow at very low levels, in order to avoid the movement if adjoining components.

Thanks to the handpieces ergonomic design, it enables the operator to work comfortably under a magnifying glass.

PCB Support Aiding In Hand Soldering

JBC has brought out a unique adaptation of their PCB supports.

Their current line single handedly holds your PCB’s at a consistent vertical level.

NOW, their new Multi-Axis Rotative PCB Support has been upgraded to help you perform all your soldering and rework jobs in any position.

With its key features listed below, the new PSS is the ideal tool allowing for fast, easy and precise PCB changing and proper positioning when hand soldering.

Key Features:

- Ensures fast and precise PCB handling in any position.

- Turn your PCB upside-down (180°) in one movement.

- Ideal for repetitive soldering jobs, saving you time and optimising workflow.

- Designed to simplify your work with or without a preheater.

- Provides up to 3 heights.

- You can turn your PCB upside-down in one movement with 180° horizontal axis swivel, vertical axis swivel and different angular positions 25º, 35º, 45º and 55º.

Desoldering Tools Have Upgraded!

JBC have upped their precision game again with their handpieces, this time with an angled desoldering iron.

This new tool performs precise desoldering in every corner of the PCB thanks to its angled design and inbuilt powerful vacuum system that seamlessly removes excess solder.

Also ensuring precise temperature control due to the integrated heating system.

Key Features:

-

Tool maintenance – Cleaning your tools is effortless with the easy-to-clean solder collector, ensuring your tool remains in perfect condition for extended use and cost efficiency.

-

Ergonomic design – This tool is designed with your comfort in mind, featuring an ergonomic grip that minimises stress on your hand and wrist. The lightweight design reduces fatigue during extended soldering sessions.

TopLine

Another booth set up at productronica this year was TopLine.

In the UK, Kaisertech serves as the exclusive distributor of Topline components, and we are thrilled to showcase a wide variety of their product range.

It was interesting to engage in conversations about the increasing popularity of bonding wire within the industry. Bonding wires electrically connect multiple layers of semiconductor chips and electrodes on a PCB. For this, extremely fine alloys such as gold, silver and copper (to name a few) are used.

These wires can be around one-tenth the diameter of a strand of hair. In terms of application, bonding wire is in everything from EVs, traffic lights, Automation robots, and many other areas of our lives.

In light of this, Topline announced that they're partnering with Tanaka Precious Metals, the premier manufacturer of bonding wire to the semiconductor industry. This partnership has allowed for the offering of single spool bonding wire purchases in the UK!

Single spool bonding wire is ideal for training, application testing, prototyping or projects requiring less than 500m of bonding wire.

This is an exciting prospect for Topline as the demand increases for bonding wire.

Material:

- Gold (Au)

- Silver(Ag)

- Aluminum (Al)

- Bare Copper (Cu)

- Palladium Coated Copper (PCC)

Apollo:

In the realm of industrial robotics, Apollo Seiko is a standout, particularly in advanced soldering solutions.

Renowned for precision and quality, their robotic soldering systems offer versatility in iron tip design, innovative solder feeding techniques, unmatched control, and adaptive technology catering to various industries.

At Productronica this year, Apollo highted a lot of the current trends in the industry and how their technologies including:

IoT Integration: Apollo is embracing the era of connectivity by incorporating Internet of Things (IoT) capabilities into their robotic systems. This enables real-time monitoring, predictive maintenance, and data-driven insights for improved operational efficiency.

Collaborative Robotics: Apollo is at the forefront of the collaborative robotics movement, where robots work seamlessly alongside human operators. This not only enhances the flexibility of manufacturing processes but also ensures a safer working environment.

AI and Machine Learning: Apollo is leveraging artificial intelligence (AI) and machine learning algorithms to enhance the learning capabilities of their robotic systems. This results in adaptive and self-improving robots that can continuously optimize soldering processes.

Energy Efficiency: With a growing focus on sustainability, Apollo is incorporating energy-efficient features into their robotic systems. This not only reduces environmental impact but also contributes to cost savings for manufacturers.

We can see that Apollo has embraced IoT, collaborative robotics, AI, and energy efficiency, reaffirming their commitment to shaping the future of the robotic industry. Manufacturers seeking quality solutions can rely on Apollo's innovative and forward-thinking approach.

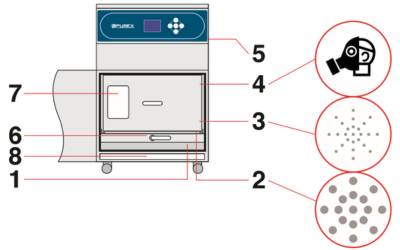

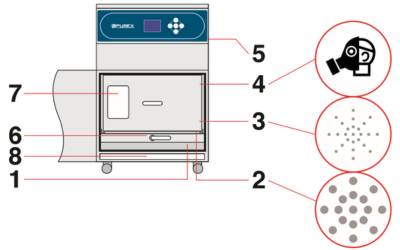

Purex:

Purex divulged into the future prospects for the market of fume and dust extraction, and from our conclusions, they appear promising.

With a growing emphasis on workplace safety and escalating government regulations concerning air quality, there is a rising demand for fume extraction solutions.

Industries are becoming increasingly concious of the potential health risks associated with exposure to harmful fumes and dust, leading to a greater adoption of fume and dust extraction systems.

Moreover, progress in technology and design has yielded enhanced extraction systems that offer improved efficiency, greater flexibility, and user-friendly features. These factors are expected to further propel market growth and something we could see developing Purex products.

In recent times, it has been a noticeable trend that industries are progressively investing in fume extraction systems to establish a safer and healthier work environment for their workforce.

The market is experiencing substantial growth, driven by the increasing number of construction projects, industrial expansions, and global infrastructure development.

With these factors in mind, Purex gave us an exclusive that they have an exciting 2024 planned for fume extraction and to keep an eye out for big changes in the first quarter of the new year.

Conclusion:

As you can see, Productronica 2023 was a busy one this year!

2024 proves to be a very exciting year for the industry with smarter technology, wider innovations, range expansions and new and improved equipment that will fasten and optimise our working processes.

Keep your eyes peeled on our website in the coming months as we make these products available to purchase online.