Ambersil are best known for providing engineers and maintenance professionals with exceptional product quality and performance, whilst maximising value for money.

As a market leader, Ambersil have rapidly developed cost-effective products, and as part of the global CRC Industries group the brand enjoys an excellent understanding of the chemical industry and global marketplace.

| Article Contents | |

| About Ambersil | |

| Adhesives | |

| Lubricants | |

| PCB Cleaners | |

| Anti-Corrosive Chemicals |

About Ambersil

With a reputation of manufacturing high grade chemical products developed to meet the most exacting standards of engineers and maintenance technicians, Ambersil have been at the heart of the industry for over 60 years.

Ambersil products are used and approved by world class companies and government organisations such as MoD, NATO, Rolls Royce, Ford, Boeing and numerous rail operators. Utilising these global connections allows them to rapidly develop and bring to market new, tested products, setting them apart from competitors.

At Kaisertech, we highly value the quality, high performance and reliability of our products.

Our Ambersil product range undergoes stringent quality control tests at every stage of product production. Their in-house technical specialists assist with the design, manufacture and testing of all products in a purpose built blending and production facility.

Therefore, you can trust in the fact that Ambersil products are of a high standard incorporating electrochemical science, causing chemical reactions that maintain and repair.

Ambersil Product Range

The Ambersil range has grown to feature over 170 products, 330 SKU’s, and continues to grow.

With Ambersils’ stamp of approval from large organisations and government bodies, including: MoD, NATO, Rolls Royce, Ford, Rail Operators, Boeing, NSF and many more, they further serve to illustrate the high performance and reliability of their products.

Adhesives

Adhesives are chemicals that can chemically overcome the pressures needed to physically separate two or more distinct substrates to chemically glue them together. Since they are frequently more effective and simpler to use than mechanical fasteners, they are employed in almost every product that is made up of two or more pieces.

What are the benefits of using adhesives in electronics?

The benefits of using an adhesive in electronics allows for faster processing times and bonding a wide variety of substances. Not only this, but the adhesive itself protects electronic components from corrosion.

Lubricants

Lubricant separates two surfaces by making a film in between them and avoids two materials i.e metal-to-metal, contact directly. This lubrication process absorbs the frictional heat produced in between the two parts.

Hence the lubricant acts as a coolant which further reduces the loss of power by decreasing the frictional forces. It also prevents machine wear.

What happens if machinery is under-lubricated?

Without the lubrication of equipment, machinery parts wear down significantly faster than its potential lifespan. In addition, the effects of under lubrication can also lead to higher energy usage and ultimately increased operating and maintenance costs.

There are a range of Ambersil Lubricant products on offer which provide highly effective results in all your workplace needs.

PCB Cleaners

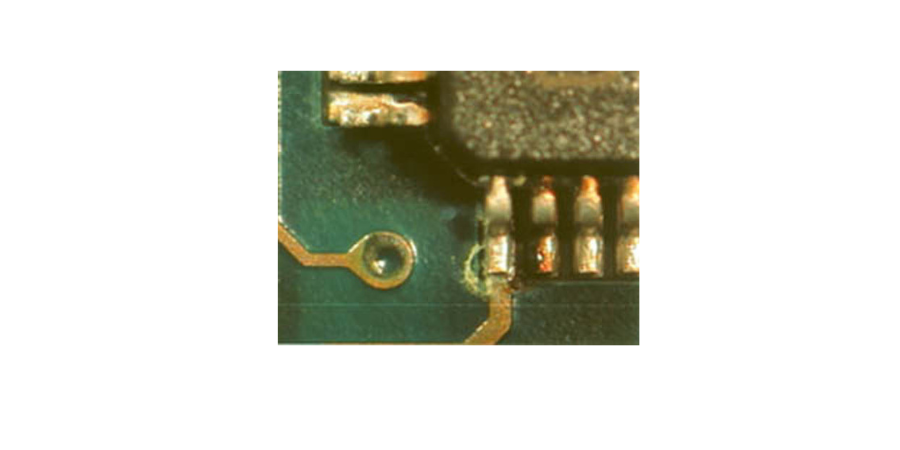

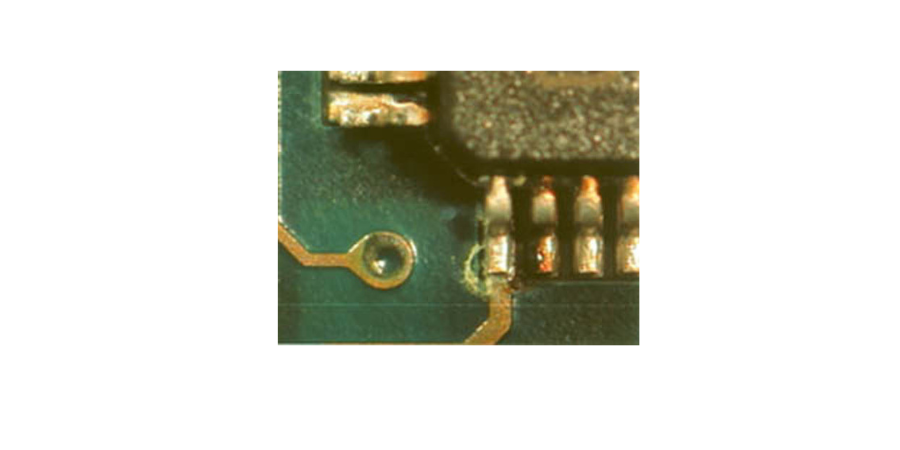

A printed circuit board (PCB) is an electronic assembly that uses copper conductors to create electrical connections between components. A printed circuit board design must include a specific set of steps that aligns with the manufacturing process, integrated circuit packaging, and the structure of the bare circuit board.

Why are PCB cleaners important in electronics?

If you are a contract manufacturer of PCB’s, the visual appearance of the board reflects on your work. A clear, greasy-looking residue around a solder joint may raise flags for your customer’s incoming QC inspectors.

If the flux residue chars and forms spots on the solder joints it may look like a true defect like a solder joint void or “blow hole”.

Flux residues left on electronic circuit boards are acidic. If they aren’t removed with a cleaning process, the residues can draw in ambient moisture from the air and lead to corrosion of component leads and PCB contacts.

These residues can generally be cleaned with a PCB cleaner. It can also remove light soiling such as thin oils, thermal paste, light flux residue, ink, solvent soluble coatings and grime.

Often agitation is needed to remove the residues, which may include a wipe, swab, brush, or an aerosol with a brush attachment.

Ambersils’ PCB cleaner has excellent material compatibility and is specifically formulated for use on delicate electronics. The cleaner evaporates quickly, leaving a clean, dry, residue-free surface.

Anti-Corrosive Chemicals

Corrosion is the process of oxidation. When oxygen bonds with the metal on the circuit board, it produces rust causing the metal to flake off and lose its valuable chemical properties.

Due to the large surface area of metal on the circuit board, it is inevitable that corrosion will occur.

What causes corrosion on PCBs?

Harsh environments in the workplace can cause electrochemical deterioration and chemical interaction on metallic wire terminals.

The corrosion of current-carrying parts and switching, as well as controlling equipment, affects the reliability and operation of all kinds of electrical facilities.

To prevent corrosion, it is highly important that a protective coating is applied as a barrier to provide a physical seal from chemical attack.

Summary

We hope this article has highlighted the importance of using Ambersil products in maintenance and cleaning of electrical products in your general working processes.

To ensure a long life-span of machinery and high quality of outputs, we strongly recommend viewing our selection of Ambersils product range.