So, you have been tasked with expanding the production line at your facility. That means investing in more furniture, seating and other equipment.

What should you think of first?

The answer to this requires you to take a holistic approach to the entire setup in your facility. We are of course referring to the ergonomic design of all furniture, equipment and processes your employees will use or undertake.

In this guide, we will walk you through how to ensure the ergonomics in your workplace are as watertight as possible.

What Does An Ergonomics Mean?

Analysing the ergonomics of a workstation or factory floor requires the evaluation of the bigger picture. It involves digging into the impact of processes on an operator over a sustained period of time.

Ergonomics revolves around designing and basing your processes for people.

The Human Factors and Ergonomics Society (HFES) develop this further:

They highlight that ergonomics is “concerned with the application of what we know about people, their abilities, characteristics, and limitations to the design of equipment they use, environments in which they function, and jobs they perform.”

Ergonomics aims at reducing the discomfort of your workforce, whilst increasing both efficiency and productivity.

This can be achieved in a number of ways, as we will outline below. But first, let’s look at why it is important.

Why Is It Important To Have An Ergonomic Workstation?

As we have alluded to above, there are consequences for neglecting the ergonomics within your working environment.

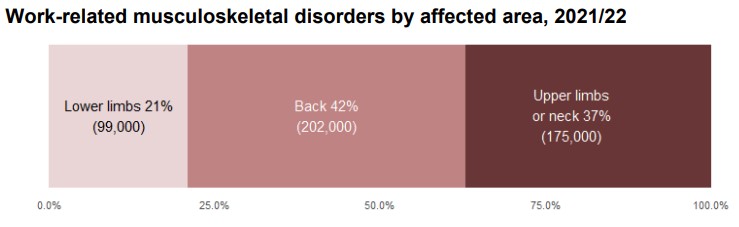

One of these specifically refers to work-related musculoskeletal disorders (WRMSDs). These will develop in a work setting due to the physical tasks that an individual conducts on a normal day-to-day basis.

Commonly WRMSDs will occur in the back or upper limbs (such as the shoulders, wrists etc).

WRMSDs will often occur where work patterns include:

- Body positions that are either fixed or constrained.

- Repetitive movements over time.

- Localised force through small joints on the body, for example, the wrists or knuckles.

- High-paced environments that do not provide sufficient resting periods for operators.

The electronics industry in particular was highlighted by an HSE report as having statistically higher than average WRMSD rates.

Consequently, MSDs of any kind can hamper an operator’s ability to work to their full capacity. This leads to drops in performance and output, poorer results, and higher rates of sick days.

How To Maintain Ergonomics In The Workplace

So now that you understand the importance of an ergonomic workstation, how do you go about ensuring the implementation of ergonomic furniture and practices within the workplace?

Here we have highlighted 4 key requirements of an ergonomic workstation.

1 - Working Height

The requirements for working height are incredibly varied from task to task. So, in terms of creating the best ergonomic environment, ensure the height is adjustable to suit the operator’s working requirements.

This is even more crucial if you have multiple operators working on the same bench

This is due to 2 main factors.

Variety Of Tasks

Tasks can fall into one of 3 categories:

- Tasks requiring accuracy.

- Light work.

- Heavy work requiring force.

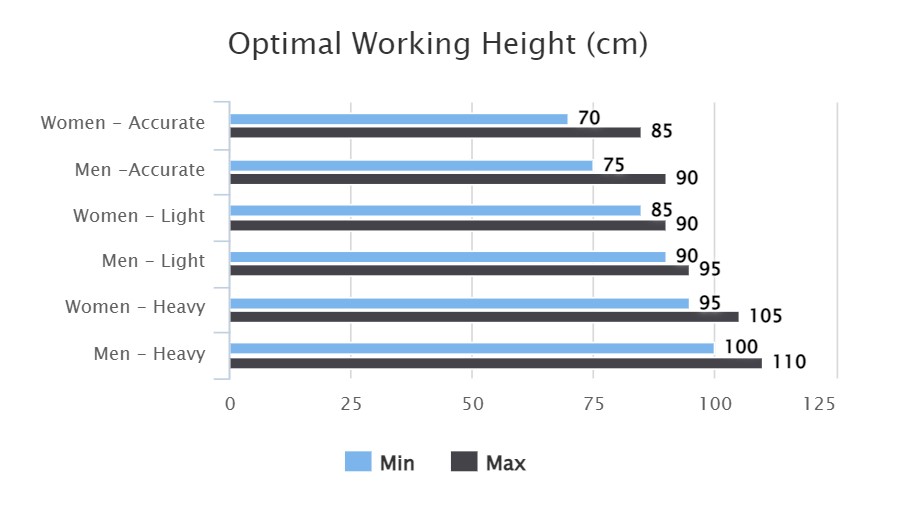

The optimal height for each varies considerably, as you can see in the diagram. Precision tasks for example will require clearer visuals, often meaning that the working surface will need to be raised above elbow height for a shorter working distance.

If an operator was then to carry out a task that required force, this working height would be insufficient. In this case, the working surface should be lowered below the elbow. This gives the operator the ability to utilise their body weight, whilst also applying more downward force.

There will also be a difference in the optimal height for both men and women (as displayed in the chart).

Posture & Seated Vs Standing Work

Over the past decade, standing work has increased in popularity. But it is still not recommended for long periods of time.

And the opposite is also true, with prolonged periods of seated work having a detrimental effect on the operators’ well-being.

Studies have shown that a hybrid of both seated and standing work can help to improve an operator’s attentiveness, learning capabilities, cognitive performance, and even memory.

So, ensuring that your workstation caters to a variety of working heights will improve its ergonomic potential.

Sizing & Accessories Of The Workstation

Space On The Workstation

One of the more obvious considerations for any ergonomically minded workstation is the correct tabletop dimensions. There needs to be enough space to ensure all equipment and furniture are in the optimal location.

If multiple operators are using the workstation, then there needs to be enough space for operators to switch between tasks and equipment.

Cramped workspaces can lead to poor posture, where the operator is required to move in unnatural ways to reach equipment, such as twisting their back, etc.

Accessibility

This point focuses on 2 central points. Those are:

- Whether the tools and equipment required by the operator are within reach.

- The actual space that is in and around the workstation.

Tool Accessibility

Firstly, let’s focus on the operator having easy access to the tools and items that their job depends on. To solve this problem, you will need to investigate the storage space and location of the workstation.

Storage – This inevitably leads to better organisation. Insufficient storage space can lead to a messy working area and directly impacts the output of the operator. All working surfaces should be free of clutter, enabling the operator to focus solely on the task at hand. Ensure that there are sufficient racking, shelves, drawers, and tool hooks. This helps to improve the overall accessibility of the workstation.

Tool Positioning – Overextending, or overreaching are common physical risk factors that can put a strain on both the neck and shoulder region. Often these movements are unnecessary and can be avoided through the addition of benching accessories, including tool balancers, keyboard trays, and torque reaction arms to name but a few.

Workspace Accessibility

Each workstation needs to be accessible, especially so that mobility in and around the workstation is seamless. This means no obstructed routes, full chair mobility, and enough space for the operator to comfortably sit.

Lighting & Vision At The Workstation

If you cannot adequately see what you are working on, then there will be a detrimental effect on the output of said work.

But there is no “one light suits all” solution. Therefore, the ability to adjust and adapt is crucial.

For example - tasks that require the utmost degree of accuracy, such as nano soldering, will require a lot more light than other tasks. Purchasing an illuminating bench magnifier would be a way to solve this.

Depending on the type of work, poor lighting can introduce an element of danger also. Soldering irons, for example, work at high temperatures, so it is crucial that the operator can see what they are doing. Even the most experienced of soldering professionals would never choose to work in a low-lit room!

Whilst it is important to state that sufficient lighting is always required, this light must be properly directed. What this means is that light needs to be directed and defused sufficiently to ensure there is no glare or strain on an employee’s vision.

Each person is different in their light preferences, so having the ability to dim and direct where appropriate is essential.

Ergonomic Seating

We have already touched on the seated vs standing debate above. So let’s instead dive into the requirements for ergonomic seating on the production floor.

This centres around 3 fundamental requirements:

- Can the backrest height be adjusted?

- Is the angle of the backrest able to be adjusted?

- Can different postures be supported in the work chair?

If you look at the chairs within your workplace and answer yes to all of the above, then perfect!

But let’s add a bit of context. The idea of the backrest is to provide support to the lumbar region of your back, promoting the natural curvature of the spine, which thus helps to alleviate pressure on the back of the spine.

An ergonomic chair should also allow the user to work in varying positions, whilst fully supporting them.

There are even solutions for standing work, with sit/stand stools providing the perfect means to take some of the weight from the legs. This will aid in reducing fatigue, where the majority of work is undertaken from a standing position.

How Can You Identify An Ergonomics Problem?

Talking To Staff

One of the best ways to identify any issue is to go boots to the ground so to speak. This involves asking the operators for their opinions on working conditions. A collaborative approach can highlight problems that you may not have been aware of. It also increases your level of commitment toward health and safety. They may well bring to the table a problem that you had never even considered.

Hazard Spotting

Take a stroll around the workplace and keep an eye out for anything that looks indicative of poor equipment or a possible hazard. This can help you be proactive and make amendments before ergonomic-related issues occur.

Review Reports

Having a look at accident reports, sickness records and more can help you to spot trends. Determining whether these may have been caused by work-related factors will give you an indication of whether you need to act. You will also get a good idea of what areas in the workplace require action.

To Conclude…

Whether it be your seating arrangement or furnishing, ergonomics should always be at the forefront of your thinking.

But if you take the advice outlined in the article above, you will ensure that the necessary precautions have been taken.

After all, operators spend large parts of their daily lives in the workspace. So ensuring they are as safe and comfortable as possible should be of paramount importance.