With the increased miniaturisation of components, devices, and PCBs in electronics, bonding wire has become a staple of the assembly process for electronics.

With this post, we aim to delve deeper into the use of wire bonding in microelectronics. In addition, we explore what bonding wire is, its forms, and examples of real-world applications.

What Is Bonding Wire?

Bonding wires electrically connect multiple layers of semiconductor chips and electrodes on a PCB. For this, we use extremely fine alloys such as gold, silver and copper (to name a few). These wires can be around one-tenth the diameter of a strand of hair.

They are in everything from EVs, traffic lights, Automation robots, and many other areas of our lives (more on this below).

Subsequently, we include bonding wire in most semi-conductor devices that exist today.

With semiconductor devices becoming smaller, the diameter of wire we use has had to become thinner to accommodate. Currently the most popular diameter of mainstream bonding wire is around 15-25 µm. This is one third of that of an individual strand of hair from your head.

As stated above, you can get bonding wire in variations of 4 main wire alloys. These are gold, silver, copper and aluminium. Below is a brief description of the performance of each alloy.

Alloys Available For Wire Bonding In Microelectronics

Gold Wires – Gold, or Au alloy bonding wires, have a high performance. This provides outstanding electrical connectivity, along with corrosion resistance, chemical stability, and workability.

Silver Alloys – Silver wires have the greatest conductivity and thermal conductivity. They provide a cheaper alternative to that of gold, and can reduce your material costs by up to 80%.

Copper Alloys – Using a Cu alloy provides supreme electrical conductivity and fusing of currents. They are in various devices such as discrete semiconductors, QFPs & BGAs. Pd coated copper wire is also available.

Wire For Power Devices – Power devices need bonding wire that works with high currents. The wire needs to withstand harsh environmental conditions. You can get thick wires, ribbon wire & many other variations.

A Bit About Tanaka

Kaisertech use a Japanese company called Tanaka for our supply of bonding wire. They have over half a centuries worth of mastery in precious metals.

Their story began in 1961, with the development of gold bonding wire for silicon transistors. At this moment in time, they were the next generation of semiconductors.

With the help of a small and dedicated team, Tanaka produced technology for the mass production of gold bonding wire. Since then the company has blossomed into a powerhouse.

For over 50 years, Tanaka has been the worlds leading manufacturer of bonding wire. They currently boast the largest global supply volume.

Core Technologies - Reasons To Use Tanaka Bonding Wire

Ultra-Fine Wire Diameters

A specialty of Tanaka is the drawing of ultra-fine precious metals. They draw the alloys through a specialist machine (known as a die) which turns the alloy into a wire shape. The use of a dozen dies reduces the diameter of the wire to as small as 10 µm. As a result, ultra-fine wires are available with lengths of up to 5000m.

High-Purity Melting – Consistent Uniformity

Specialised melting technology creates the high-purity alloys with the introduction of additive elements on the ppm level. Drawing and heating treatment allows the wire uniformity, even with the slimmest of wire diameters.

Micro Rolling – No Burrs

Rolling an alloy through rotating rollers produces thin and flat ribbon wires. Subsequently, Tanaka’s manufacturing technology produces burr-less end-facing wire. This is available in diameters as low as 100-600 µm. These products use mirror rolling to reduce surface irregularities to an average of 1 µm or less. Automotive devices require high bondability also. The micro rolling caters to this thanks to surface cleanliness control. This is equal to that of other bonding wires in the Tanaka range.

Precious Metal Coating

Some semiconductor mounting requires the use of proprietary processes. For this, Tanaka manufactured pure wire alloys with precious metal coatings such as palladium (Pd). Subsequently, Tanaka has achieved dramatic improvements in the oxidisation and corrosion resistance of the copper wiring when coated with the Pd.

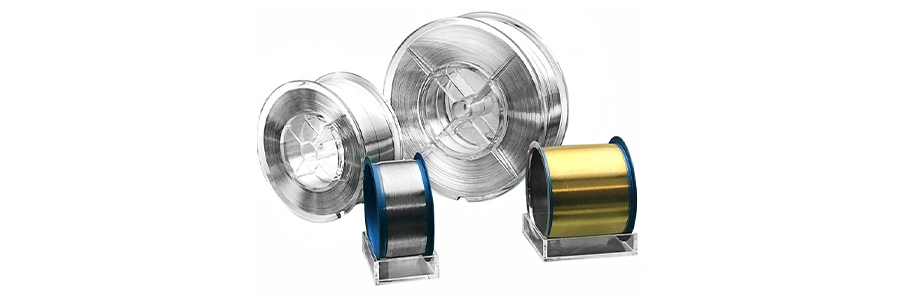

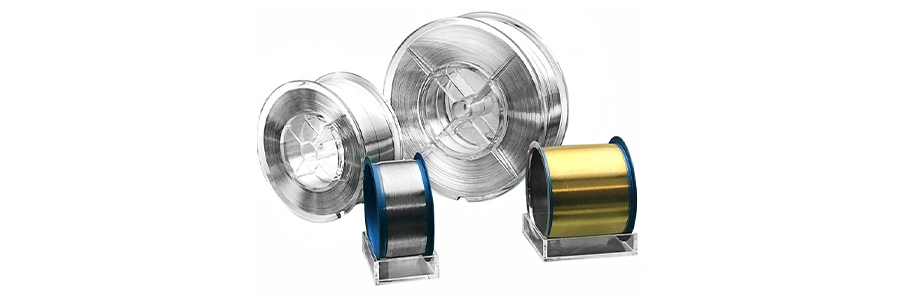

Smaller Spool Lengths

One of the most attractive prospects for using Tanaka bonding wire, is the production of smaller spools of wire. Where you need low amounts, there is no need to buy more wire than you would use. Smaller ½ inch spool sizes are available. Therefore, this ensures you only spend your budget on the bonding wire you will be using on your application.

Case Study Of Applications Of Bonding Wire

Medical Industry

The medical industry uses Bonding wires in many different pieces of equipment. Particularly soft gold wire.

Gold provides a marker in minimally invasive procedures. For example, it is in catheterisation and included in guide wires.

High-purity and high-strength gold bonding wire can also enhance the accuracy of radiation therapy. X-rays do not pass through the alloy, making it highly visible (high x-ray impermeability).

Smart Phones

Other Devices & Applications

Similarly, there are several other industries where bonding wire is vital in the production process. This includes:

- Automotive – EV Production Particularly

- Clean Energy – Solar Panelling

- 5G Technology

Check out the infographic below. This shows further industries that rely on the use of bonding wire.

Manufacturing Of Tanaka Bonding Wire

The manufacturing process for Tanaka bonding wire is precise. It is under and under strict cleanroom conditions. Thus, this prevents any kind of cross-contamination catering to a consistent bonding wire spool.

The process is as follows:

Melting – The high-purity metals along with any trace amounts of additive elements, are melted together. The alloys are then cast and ready for the next stage of the process.

Drawing – Dies, the drawing tools for the wire, are used to thin out the metal. After that, they draw the alloys into wires.

Annealing – The wire must then be annealed. This restores elasticity to the metals through the application of heat. By doing this, it changes the crystalline structure, and hardness adjusted.

Coating – A coating of precious metal is then applied to the surface of the wire. This provides anti-corrosion, anti-oxidisation, and various other functions.

Winding – The finished wire is then wound in a spool, with care taken to ensure that no damage occurs. 2 inch and half-inch spools are available. This means you can better select the amount of bonding wire you need for your application.